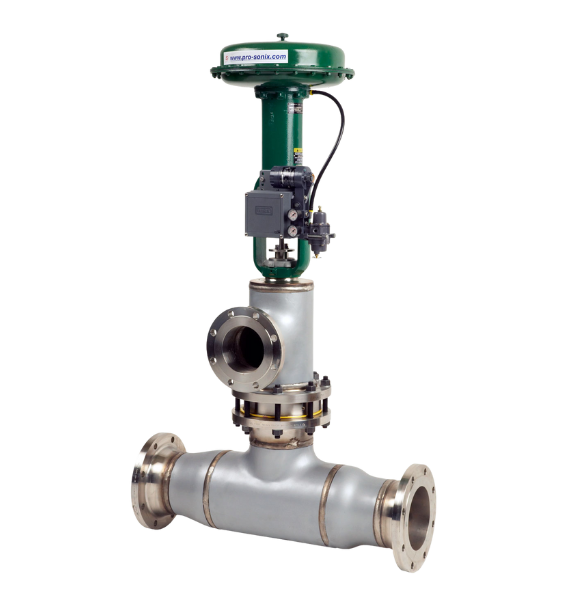

Features and Technology

PSX I-Series Inline Heater with PSX Jet Diffuser

- Steam injection heater with internally modulated steam control

- Radial Multi-port Steam Injector design assures uniform heating for stable & smooth operation

- Internally Modulated steam flow control achieves choked flow conditions for sonic flow (high velocity) steam injection

- Precise temperature control of +/- 1 deg F

- Energy savings results from low pressure drop (typically 1-2 psig)

- Self cleaning design eliminates plugging/fouling with no mineral or scale build-up.

- Handles flow rates from 1 - 15,000 gpm.

- Simplified installation with inline design and positional steam inlet