What Would It Mean to Meet—or Exceed—Your Production KPIs?

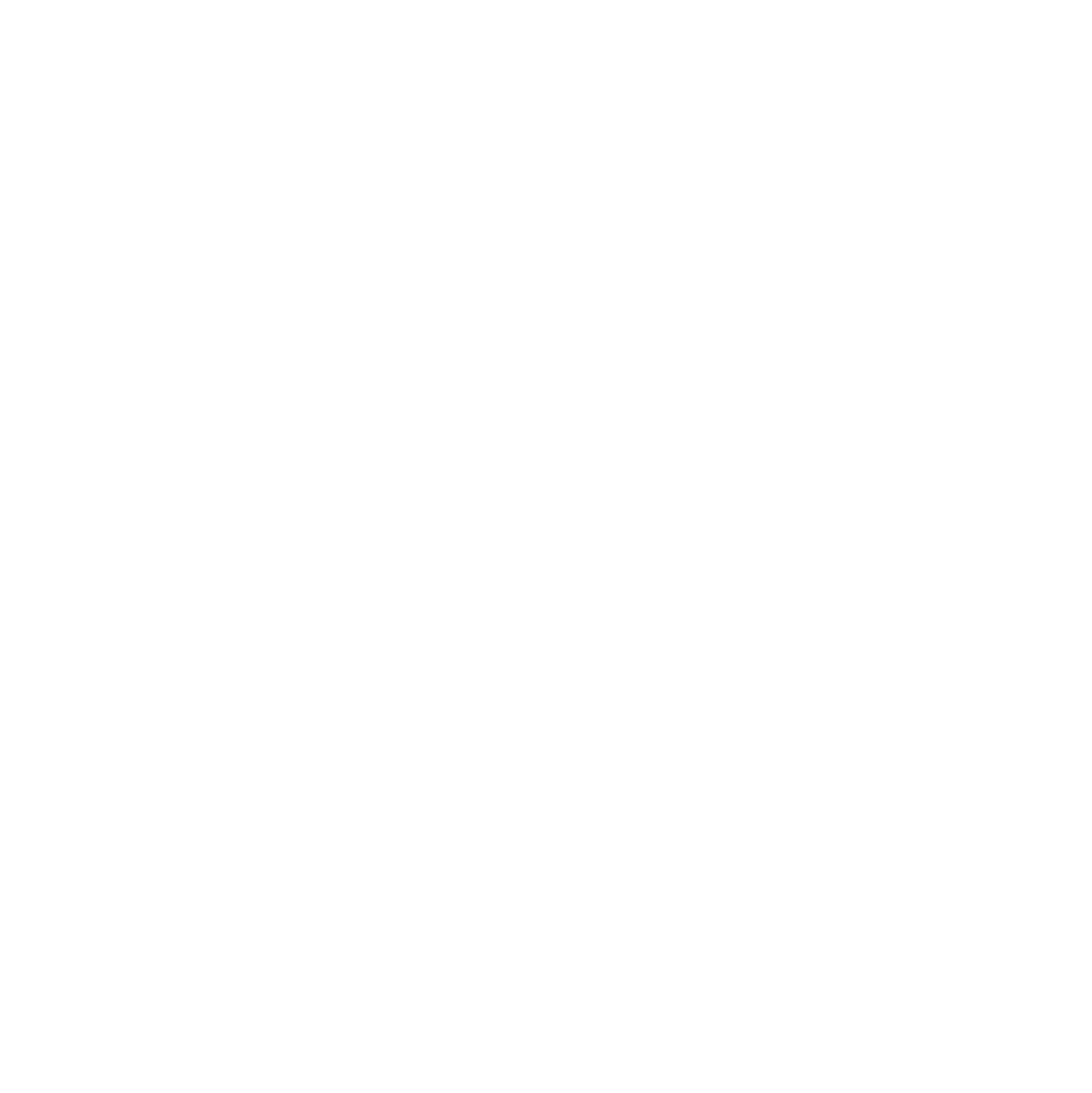

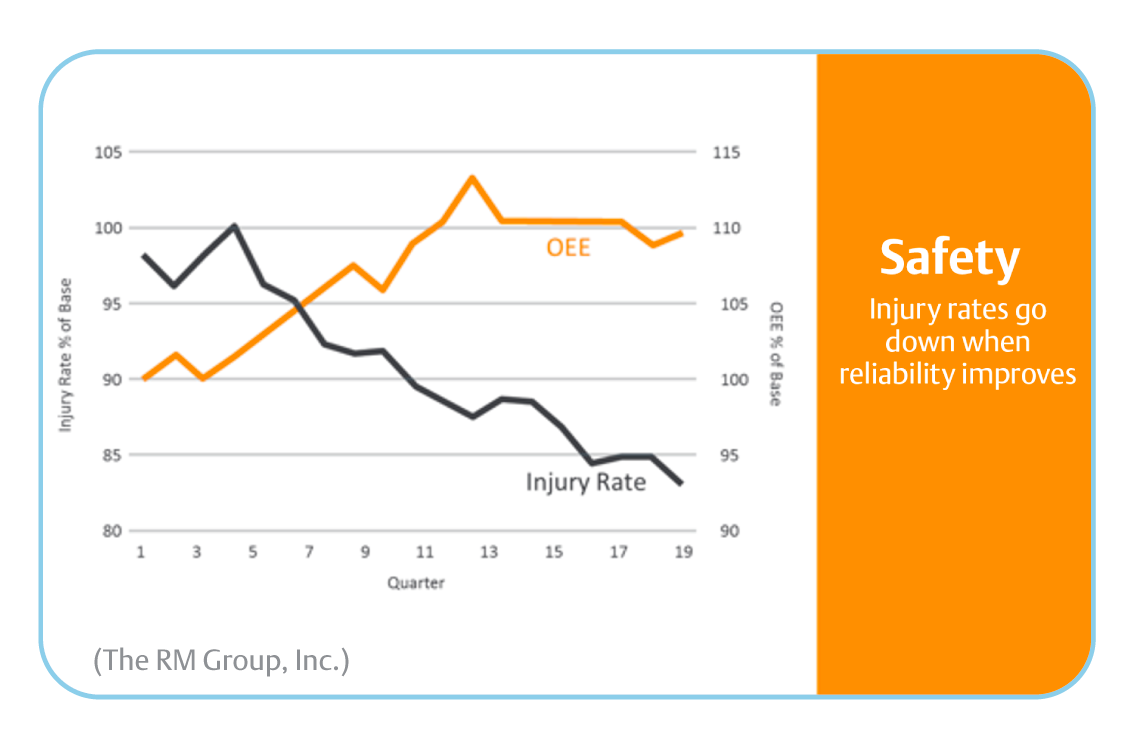

- You could reduce downtime by 60% each year. What would you do with that extra production capacity?

- You could extend your preventative maintenance schedule or consolidate your spare parts inventory. How much money and resources would you save?

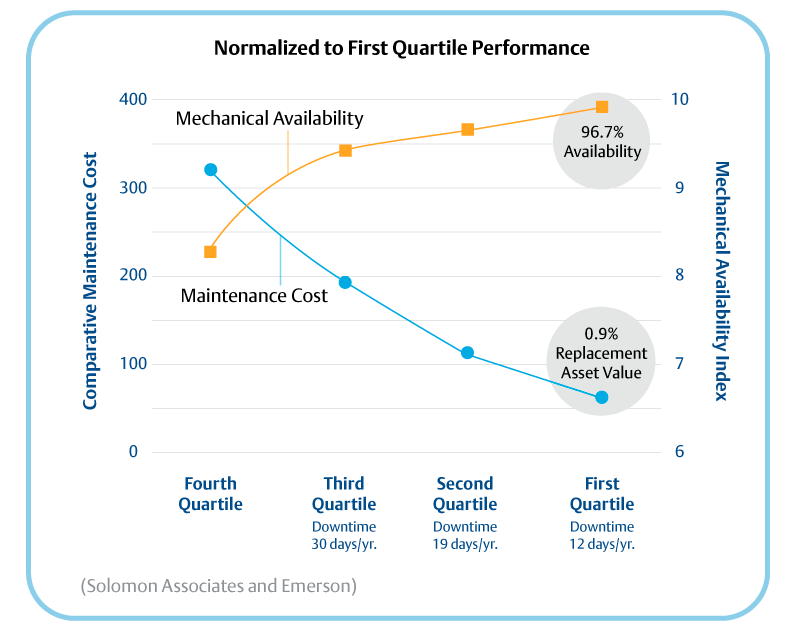

- You could have better access to, and more accurate data. Would that help you make more informed business decision?